Nf system

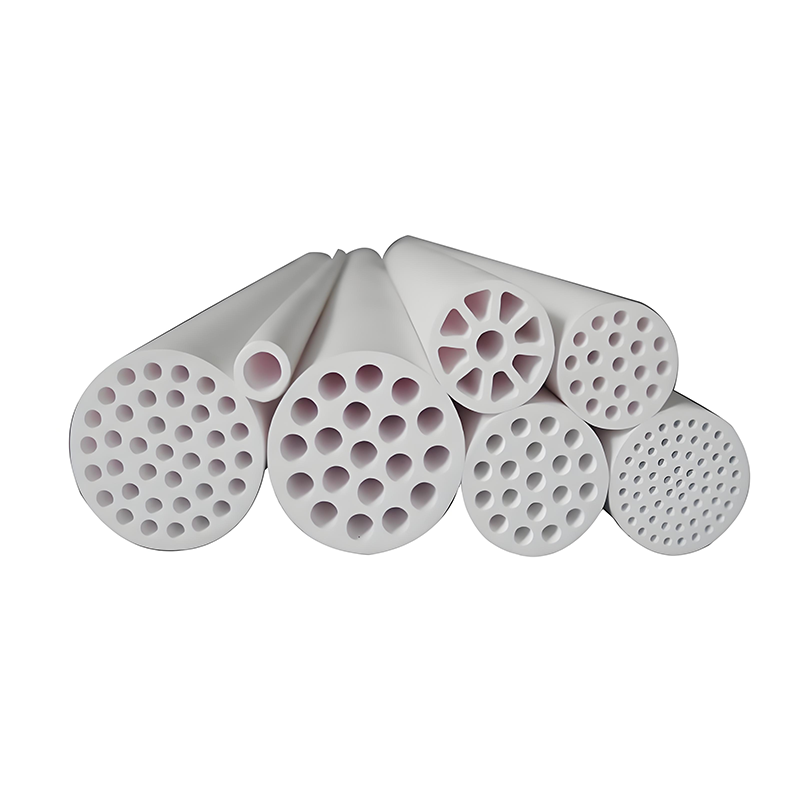

Did you know that we can remove microscopic pieces of dirt from water or even other liquids? This may sound difficult, but the old solution is something called filtration! Filtration is a process used to separate solids from liquids or gases, which is done using a filter medium that permits the fluid to flow through while trapping the solid impurities. One special type of filtration is referred to as nanofiltration or shorten to nf. This ultrafiltration system works with special membranes called nf membranes, which are like very fine nets or sieves that can catch even the dust particles not visible to the naked eye. These Vocee Membrane, membranes are crucial because they help maintain the cleanliness of our water and other fluids. Now, let’s understand nf technology and see how it can be beneficial for various sectors.

NF technology is a powerful technology that improves applications in factories. nf filters were used to clean their liquids, many businesses use them, from manufacturers of food, drinks, or medicine, to manufacturers of different chemicals. These companies can assure that their products are people-consuming safe by using nf technology. Especially for products we ingest (eat or drink), we want to make sure they do not contain anything harmful etc. With nf filters, businesses can also comply with health and safety standards; another win-win for everyone involved.