Submerged mnembrane bioreactor

Submerged membrane bioreactors are really cool technology that help us clean dirty water. Ever wonder where the water goes after you wash your hands or take a shower? Submerged membrane bioreactors can lend a hand.

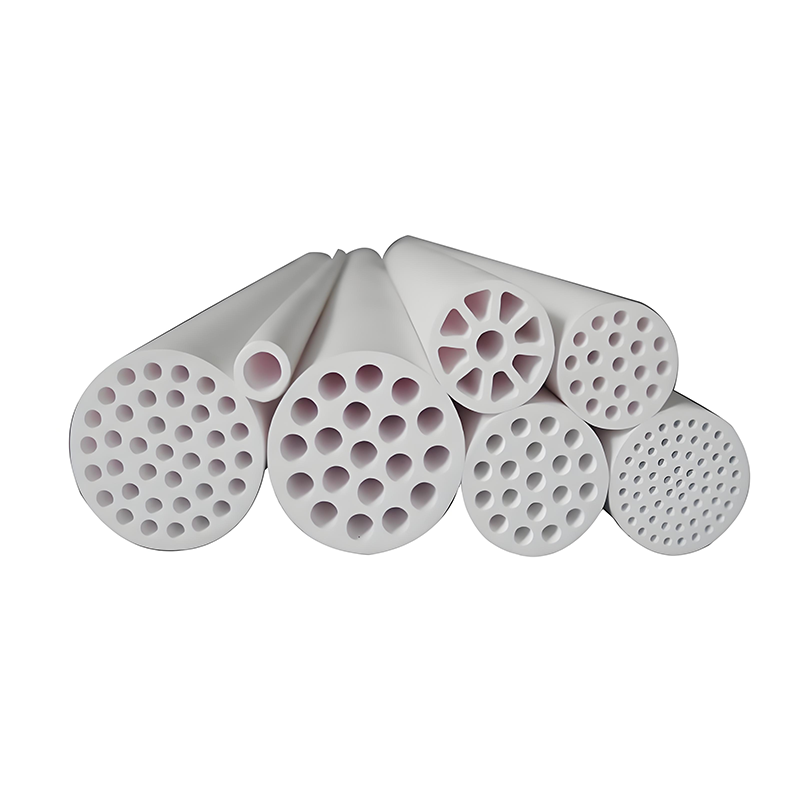

Let’s look at how underwater membrane bioreactors operate. Think about a tiny filter so minuscule that you couldn’t see it with your eyes. This particular type of filter is known as a membrane. When you put this membrane under water in a large tank of film, dirty water, such as water that may come from your home or factory, something magical happens. The membrane is like a smart bouncer that only allows clean water through, while grabbing onto all the filth stuff like dirt, germs and other nasties. Isn’t that cool?