Industrial filtration system

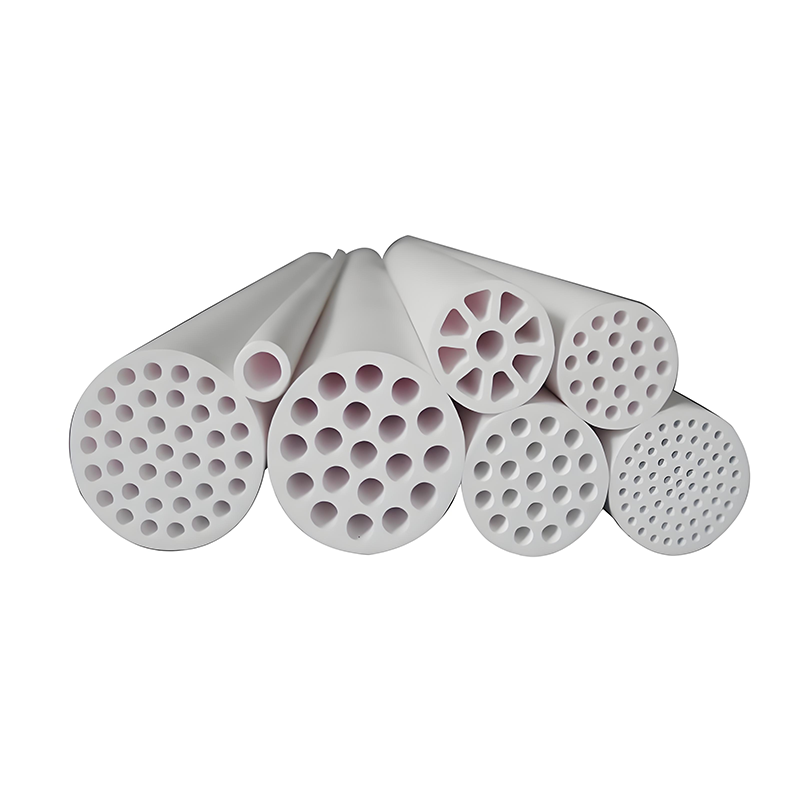

Industrial membrane filtration system operate by drawing a substance, such as a liquid or gas, through a filter. The choice of material needs to depend on what is to be filtered out and this filter can be prepared out of different materials. The filter is specifically designed to trap specific materials or pathogens. When the substance passes through the filter, the less desirable substances can be arrested heartily inside the small holes or pores of the filter.

Good Quality: Filtration systems are very useful as they help eliminate dirt and harmful materials from the fluids and gases. This translates into better quality of the final T product, important in industries where safety and standards are important. The end product can be used in various environments because it is safer and more reliable when impurities are removed.