Textile wastewater reuse

wastewaterToday, textile wastewater is one of the big problems in the world. When factories produce clothing, they need a lot of water and chemicals. Textile wastewater is such dirty water. And we can damage the environment if we don’t clean it up properly.

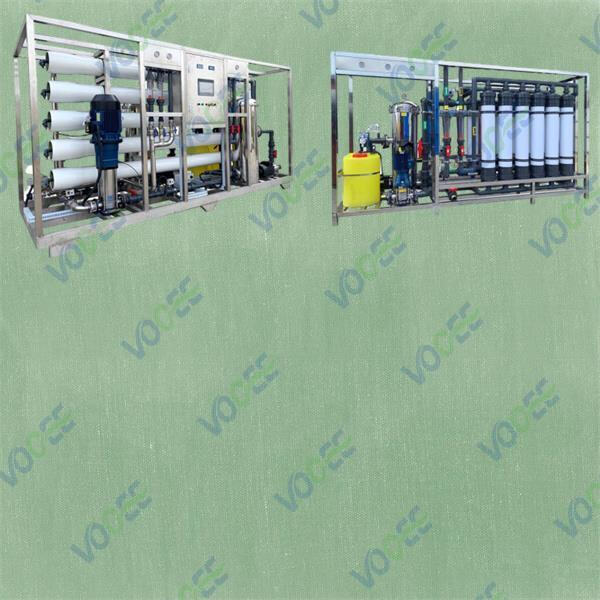

There are ways to start to alleviate this issue, one such solution is to recycle water from textile plants. Companies like Vocee Membrane are developing new methods like the Water treatment system to clean the water so it can be reused. This is critical since it conserves water and saves our planet.