เนื่องจากความจำเป็นในการอนุรักษ์สิ่งแวดล้อมและทรัพยากรน้ำเพิ่มมากขึ้น ภาคอุตสาหกรรมและเมืองต่างให้ความสนใจกับระบบบำบัดน้ำเสียที่มีประสิทธิภาพ คุ้มค่า และยั่งยืนมากยิ่งขึ้น เทคโนโลยีเยื่อหอยฟิเบอร์กลวงได้กลายเป็นหนึ่งในตัวเลือกที่ได้รับความนิยม เนื่องจากมันสามารถให้กำลังการกรองสูง มีขนาดเล็ก และต้องการพลังงานต่ำ บทความนี้กล่าวถึงการเปลี่ยนแปลงของการใช้เยื่อหอยฟิเบอร์กลวงในกระบวนการบำบัดน้ำเสียในหลายด้าน

หลักการทำงานของเยื่อหอยฟิเบอร์กลวงในระบบบำบัดน้ำเสียเป็นอย่างไร?

แผ่นใยกลวง แผ่นใยกลวงถูกผลิตและประกอบด้วยเส้นใยที่มีรูพรุนเล็กๆ ลักษณะคล้ายฟางที่เปราะบาง ถูกจัดเรียงรวมกันเป็นมอดุล น้ำเสียจะไหลผ่านเส้นใยเหล่านี้ และน้ำสะอาด (น้ำซึมผ่าน) จะไหลออกจากช่องพรุนของแผ่นใย โดยที่มลภาวะจะถูกทิ้งไว้เบื้องหลัง มีอยู่สองระบบที่มีลักษณะเฉพาะเจาะจง:

แผ่นใยจุ่ม (MBR - Membrane Bioreactor)

แผ่นใยถูกจุ่มลงในถังบำบัดทางชีวภาพโดยตรง

การเป่าลมเพื่อป้องกันการอุดตัน ช่วยรักษาประสิทธิภาพการใช้งานในระยะยาว

การกรองแบบไหลขวาง (Cross-Flow Filtration)

น้ำไหลผ่านพื้นผิวของแผ่นใยในแนวเฉียง ช่วยลดการอุดตัน

เหมาะสำหรับน้ำเสียที่มีของแข็งสูงหรือน้ำมันเป็นองค์ประกอบ

การประยุกต์ใช้งานหลักในการบำบัดน้ำเสีย

การบำบัดน้ำเสียในเขตเมือง

เครื่องปฏิกรณ์ชีภาพแบบแผ่นใย (MBRs) ใช้แผ่นใยกลวงในการ: บำบัดน้ำเสียให้ได้คุณภาพสูง

· สร้างน้ำทิ้งที่มีคุณภาพดีเพื่อนำกลับมาใช้ใหม่ (การนำน้ำทิ้งกลับมาใช้ใหม่ผ่านการชลประทานและกระบวนการอุตสาหกรรม)

· กำจัดแบคทีเรีย ไวรัส และของแขวนลอย โดยไม่ต้องใช้สารเคมีในการฆ่าเชื้อ

· ลดการเกิดตะกอนมากถึง 30-50 เปอร์เซ็นต์ เมื่อเทียบกับระบบแบบดั้งเดิม

การบำบัดน้ำเสียอุตสาหกรรม

เยื่อหุ้มเส้นใยกลวงมีประโยชน์ในอุตสาหกรรมต่าง ๆ เช่น อาหารและเครื่องดื่ม ยา เส้นใย และสารเคมี เนื่องจาก:

· แยกน้ำมันออกจากน้ำเสียอุตสาหกรรมปิโตรเคมี

· กำจัดสีและสารให้สีในน้ำทิ้งจากอุตสาหกรรมสิ่งทอ

· กู้คืนผลพลอยได้จากอุตสาหกรรม (เช่น โปรตีนและเอนไซม์) ในน้ำทิ้งจากการแปรรูปอาหาร

ระบบที่กระจายตัวและมีขนาดเล็ก

ระบบที่ใช้เส้นใยกลวงมีประสิทธิภาพในพื้นที่จำกัด:

· ชุมชนชนบทที่มีโครงสร้างพื้นฐานต่ำ

· การใช้งานในทะเลและการบำบัดน้ำเสียในพื้นที่นอกชายฝั่ง

· ระบบปฏิกิริยาบำบัดน้ำที่สามารถใช้ได้ในช่วงเวลาฉุกเฉินในเขตภูมิประเทศที่เสี่ยงต่อภัยพิบัติ

ข้อดีเมื่อเทียบกับวิธีการบำบัดแบบดั้งเดิม

ประสิทธิภาพการกรองสูง - สามารถกรองอนุภาคขนาดเล็กได้ตั้งแต่ 0.010-0.1 ไมครอน (แบคทีเรียและไวรัส)

พื้นที่ติดตั้งเล็ก - ต้องการพื้นที่เพียง 50-70 เปอร์เซ็นต์ของพื้นที่ที่ใช้สำหรับเครื่องทำให้ใสแบบดั้งเดิมและตัวกรองทราย

การใช้สารเคมีน้อยลง - ลดการใช้สารตกตะกอนและสารฆ่าเชื้อ

ประหยัดพลังงาน - ใช้แรงดันต่ำเมื่อเทียบกับเมมเบรนแบบ spiral-wound

เหมาะกับระบบอัตโนมัติ - เชื่อมต่อและทำงานร่วมกับ SCADA และการตรวจสอบ IoT ได้ง่าย

ปัญหา และ วิธี แก้ไข

การอุดตันของเยื่อ การล้างย้อนและใช้อากาศทำความสะอาดเป็นประจำ

ต้นทุนสูงมากในระยะแรก แต่ประหยัดค่าใช้จ่ายในระยะยาวเรื่องตะกอนและค่าบำรุงรักษา

การอุดตันจากของแข็งสูง ต้องมีการกรองขั้นต้น (เช่น ตัวกรองแบบตาข่าย)

แนวโน้มในอนาคต

เมมเบรนอัจฉริยะ ช่วยทำความสะอาดเองและตรวจจับการอุดตันแบบเรียลไทม์

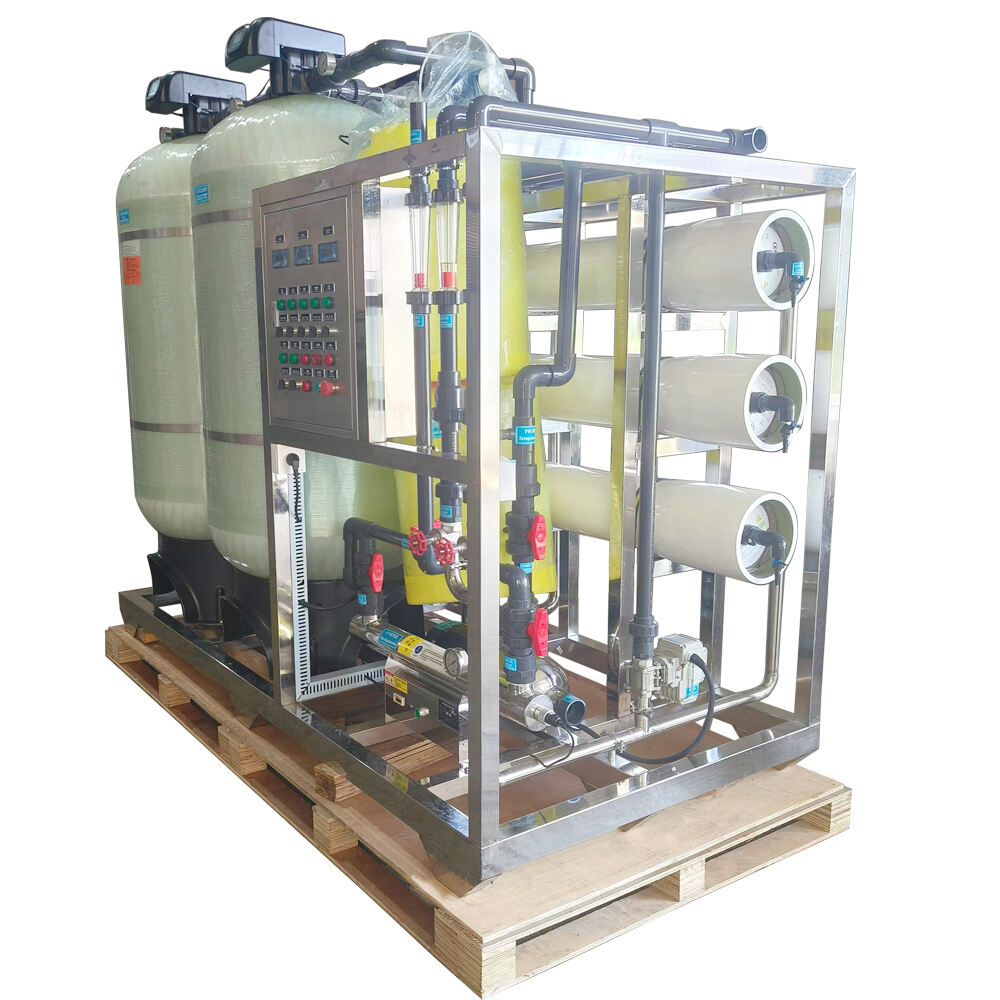

ระบบไฮบริด ที่ใช้เส้นใยกลวงร่วมกับ RO, UV หรือการทำให้เกิดออกซิเดชันขั้นสูง

แปลงของเสียเป็นทรัพยากร 2 - ผลิตก๊าซชีวภาพ สารอาหารและน้ำที่ผ่านการรีไซเคิลจากน้ำเสีย

สรุป

เมมเบรนกรองแบบเส้นใยกลวงเป็นทางเลือกที่เป็นมิตรต่อสิ่งแวดล้อม ขนาดกะทัดรัด และสามารถขยายระบบได้ ซึ่งตอบสนองความต้องการหลักในปัจจุบันของการบำบัดน้ำเสีย ไม่ว่าจะเป็นการใช้งานในระบบเทศบาล อุตสาหกรรม หรือระบบที่กระจายตัว เทคโนโลยีนี้ให้การันตีถึงน้ำที่สะอาดขึ้น ต้นทุนการดำเนินงานที่ลดลง และมาตรฐานด้านสิ่งแวดล้อม

เราเป็นบริษัทชั้นนำที่ให้บริการระบบเยื่อใยกลวงประสิทธิภาพสูง ที่บริษัท แควนต์โจว โวซี เมมเบรน เทคโนโลยี จำกัด ซึ่งเหมาะกับความต้องการในการบำบัดน้ำเสียของคุณอย่างแม่นยำ แจ้งให้เราทราบเพื่อหารือกันว่า โซลูชันของเราจะช่วยเสริมศักยภาพกระบวนการของคุณได้อย่างไร!