استراتيجية تطبيق تقنية غشاء السيراميك

عصير جوز الهند، كمشروب بروتين نباتي طبيعي، غني بالإلكتروليتات والحمض الأميني والفيتامينات. ومع ذلك، بسبب درجة浑ه العالية، وحساسيته للأكسدة والتلوث الجرثومي، غالباً ما تواجه طرق المعالجة التقليدية التحديات التالية:

1) خسارة النكهة وتدهور المواد الغذائية ناتجة عن التعقيم عند درجات حرارة عالية؛

2) كفاءة منخفضة لتصفية السيليكا الحيوية وإنتاج النفايات الصلبة؛

3) المخاطر المتبقية من مصفٍ كيميائي.

تدفق العملية:

المعالجة المسبقة : يتم سحق لحم جوز الهند ويتم فصله بشكل مركزي للحصول على عصير جوز هند مرشح بشكل خشن (pH 4.5-5.5،浑浊度 >100 NTU);

ترشيح الغشاء السيراميكي :

مواصفات المعدات : غشاء سيراميك بحجم مسام 0.2 μm، وضع ترشيح التدفق العرضي، درجة حرارة التشغيل 20°C;

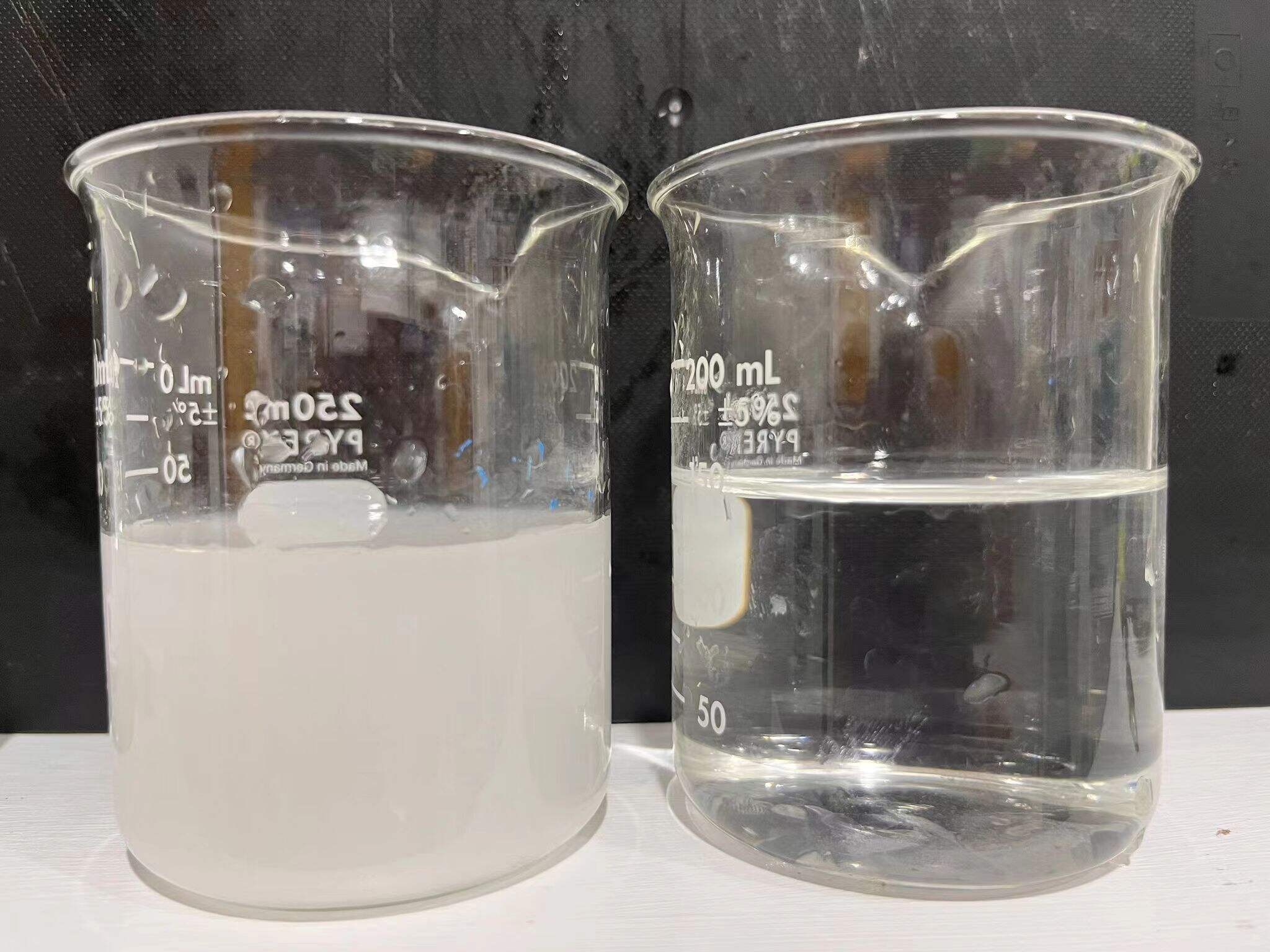

أداء الترشيح : احتباس الجسيمات الكولوئيدية وجزيئات الدهون والميكروبات (معدل احتباس البكتيريا >99.9%)، زادت نسبة النفاذية الضوئية إلى أكثر من 98%;

المزايا التقنية

تعزيز الجودة :

احتفاظ النكهة الطبيعية والمغذيات الحساسة للحرارة (مثلاً، معدل احتفاظ فيتامين C >95%);

عكورة المنتج <5 وحدة NTU، تمديد فترة الصلاحية إلى 12 شهر (عند درجة حرارة الغرفة).

تحسين التكلفة :

تقليل استخدام السيليسيد بنسبة 80٪، تقليل COD لمياه الصرف بنسبة 50٪؛

تحسين كفاءة خط الإنتاج بنسبة 30٪ (ترشيح مستمر، بدون تغيير متكرر للفلاتر).

الفوائد البيئية :

لا تحتوي على إضافات كيميائية، متوافقة مع معايير شهادة الأغذية العضوية؛

مدة حياة وحدة الغشاء >5 سنوات، قابلة لإعادة الاستخدام.